How much unplanned downtime does your plant have in a week?

There are two types of downtime: Planned, where machines may need maintenance, upgrades or changeovers. And unplanned. Unplanned downtime is the one plant managers dread the most. Unplanned downtime can amount to hundreds of hours of lost productivity. This can lead to lost revenue, late order fulfillments, and wasted manpower on the packaging line.

Unplanned downtime occurs when inventory is not found, or hasn’t been ordered for the particular job. When tooling is discovered broken or is not where it’s supposed to be. When manual scheduling is used and does not show issues in real time.

HiFlow MIS software for packaging manufacturers offers technology that will minimize your downtime.

Video Overview

Is HiFlow the correct fit for your company? How does it work? What kind of features does it offer? Watch a brief overview.

How is HiFlow different from other MIS/ERP systems? What is a workflow analysis? How do I know if you can help my company? I have more questions…We would love to answer your questions and find out all about your company and its needs.

5 Ways an MIS/ERP Optimizes Workflow and Minimizes Your Downtime

Digital transformation offers a solution, especially in today’s tight labor market. One way to accomplish this is using Management Information Systems, or MIS . An MIS integrates technology into all areas of a business, fundamentally changing how you operate across the packaging business ecosystem, from initial inquiry by a customer to delivering the end product.

Connecting all of your business platforms with real time software tools reduce downtime incidents and costs. Technicians use mobile devices, such as smartphones, tablets, barcode scanners to perform tasks. Information is shared with decision-makers in real time, empowering them to take immediate action.

1. One, fluid end-to-end system

With end-to-end integration from estimating through scheduling, production, shipping, and accounting, HiFlow facilitates the collection and sharing of information as per client preference. This smart package software is able to automate workflows and optimize packaging operations by recommending and planning the most efficient allocation of resources

- Complete end-to-end business integration

- One integrated system that removes touch points and increases efficiencies

- Business Intelligence and ‘smart’ packaging software

- Customer portal tools

- Estimating and production scheduling for label, folding carton, and flexible packaging workflows

2. Automation across all business departments

- Shared information accelerates workflows and reduces errors

- Visibility increases into the profitability of materials, jobs, customers, and more

- ‘Smart’ software can automate scheduling and plant optimization

- Maintains lean inventories, track inventory movement and WIP

- Predictive and preventative maintenance that boost uptime and keeping production running.

3. Information in a single, central database

By centralizing the company’s information in one dynamic database, HiFlow promotes effective sharing and communication between departments, among employees, and even externally to and from valued customers. With centralized data management, businesses can optimize processes and cut their overall costs. Compared to maintaining multiple systems, the maintenance of a single, central server is far more efficient especially if a company has operations in multiple locations

- Collect, store and retrieve information in a single system safely, while having complete access across the company.

- Eliminate manual processing of data

- Secure and control data for regulatory compliance

- Data is always up to date, and available in real time

- A central repository of data allows operational efficiency

4. Real-time visibility into operations with easy to use interface

The HiFlow Job Production Workflow diagram populates job information and workflow after an estimate is created. The information from the job is then stored in the database where the job is continually updated with data – data from the estimate, from any changes planning makes, adjustments to scheduling and production providing high levels of automation in end-to-end configurations controlling all aspects of production and administration. Shop floor can access any job information instantly.

It allows for swifter decision-making since all data is now in real time. As the workflow diagram continues to do its job and similar jobs run in your plant, the AI in the system continually assesses data and will ultimately optimizes production workflow.

5. Business Intelligence is instantly available

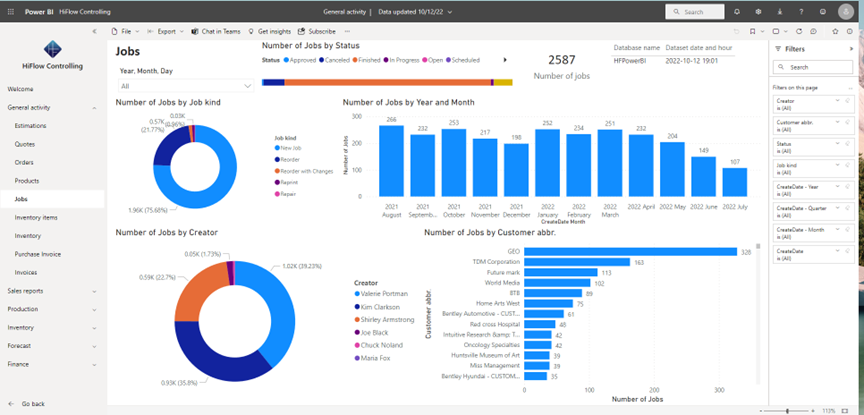

Know information about when and why downtime occurs. Managers and decision-makers are able to quickly report on and analyze their company’s information from an enterprise-wide view, down to very specific report criteria through a variety of visual performance dashboards. HiFlow’s built in advanced reporting feature, Microsoft’s Power BI, feeds management information critical to solving downtime issues. With visual ‘what-if’ scenario generators, they can easily understand the potential effects of changing workflow parameters to increase productivity and reduce downtime.

What are you waiting for?

Check out our world-class manufacturing and management solutions to increase your packaging business productivity and decrease downtime in your plant.

Schedule a tour of HiFlow.

Which Option is Right for You?

Find Out More About HiFlow

HIFLOW SOLUTIONS COMPLETE SYSTEM

HiFlow Solutions MIS software is an end-to-end management information system with tools that automate workflow and business processes…

CUSTOM SOFTWARE SOLUTIONS

HiFlow’s core management information system can be customized to suit your unique requirements. Based on your preferences for hosting and database….

MES & MACHINE INTEGRATION

Eliminate touches, decrease errors and downtime, and instantly collect data by connecting HiFlow’s sensor interface directly with your shop floor equipment…

SOFTWARE DEVELOPMENT

One of the big reasons companies look for custom business software development services: Why not develop your own 100% custom solution…