Workflow Management for Commercial Printers

Find out more!

How to Choose an Ideal Print Workflow Management Software

Every manager knows immediately when workflows are broken.

In fact, many print businesses are aware they have some issues with print workflows, but persistent time wasters often go unaddressed. How to address workflow breaks or leaks: look at a series of common repeatable processes and automate them. Look at places where lots of time is spent doing manual tasks, like moving paper tickets from department to department. Or re-entering data for reports. The first step is identifying areas where there are time leaks…

How do you know if your print workflow is broken?

A bottleneck is a choke point in the production workflow that obstructs the throughput of job volume. Your workflow has bottlenecks when equipment breaks down or when an external event ( a power outage, lockdown ) interrupts the production sequence. Most of the time, however, bottlenecks are the result of ongoing but subpar manufacturing routines – a condition that workflow automation can cure. A factor seen as most problematic is relying on expensive labor or high-touch processes. According to Pat McGrew, one of the key ways to diagnose a workflow problem is to “walk your workflow” from job entry through delivery, identifying each touchpoint (human interaction) with the job along the way. Once you’ve done that, it’s time to look for print workflow solutions.

Print Workflow: Optimizing through Automation

In the commercial print marketplace, and for many smaller print businesses, automating their printing workflow can seem like a daunting – and expensive – challenge. However, the past few years showed us that without a large degree of technological innovation, businesses will languish; but those who have adopted new technology make real inroads in the market. Meeting the needs of today’s demanding customers means developing a fast and efficient workflow.

According to Lois Ritossi, High Rock Strategies, doing this correctly requires more than just following the right steps. Organizations must create new workflows to take advantage of innovative technologies and achieve exacting standards. One way to do just that is to invest in an MIS for print.

What are the Benefits of an Optimized Print Workflow?

Again, Pat McGrew, of McGrew Group. “If you make your workflow really efficient, you add capacity to your throughput,” McGrew states. “You eliminate those bottlenecks. You make it possible to bring more work in, spend less time processing it, and more time printing it and getting it out the door, and getting paid for it.”

Automating your print production workflow improves financial outcomes, increases productivity in production tasks and ultimately increases production throughput.

Studies in print workflow, such as the NAPCO Research survey, show that Investments in workflow automation lead to profit. A highly automated and optimized workflow produces more jobs per day than companies with less automation . By minimizing non-chargeable time, an optimized print workflow leads directly to profitability.

What’s the benefit of implementing an MIS?

What you get-

- Improved efficiency of information flow and overall procedure quality

- Reduced communication errors within the employees and different teams

- Easy access to customer and employee data

- Increased company profits

- Reduced chances of failures, remakes

- Improved productivity and time management of tasks

- Elimination of errors while invoicing while reducing the invoicing time

- Increased retail margins and actual costing data

- Improved customer service

- Minimized paperwork with reduced cost and waste

Why Choose HiFlow MIS?

HiFlow is a flexible Management Information System developed to automate the processes from estimate through production to invoicing, designed by our industry experts for packaging, label, and print production. HiFlow MES module allows real time data from sensors to compare estimates, job tickets with actual production costs.

We aim to provide the perfect solution to any problem area of your plant. We configure the software to fit the infrastructure and needs of your company. We provide scalability in our print workflow system so it grows with your organization. IN fact, our team of experts and developers assess the future needs of the company in their initial evalutation.

An investment in print workflow automation may seem large now, but holding back may mean holding back growth for your company– a mistake that no printing business can afford to make in an environment where growth and profit increasingly belong to those adopting Smart Technology solutions. HiFlow can be your solution to workflow optimization.

What features should an MIS/MES system have?

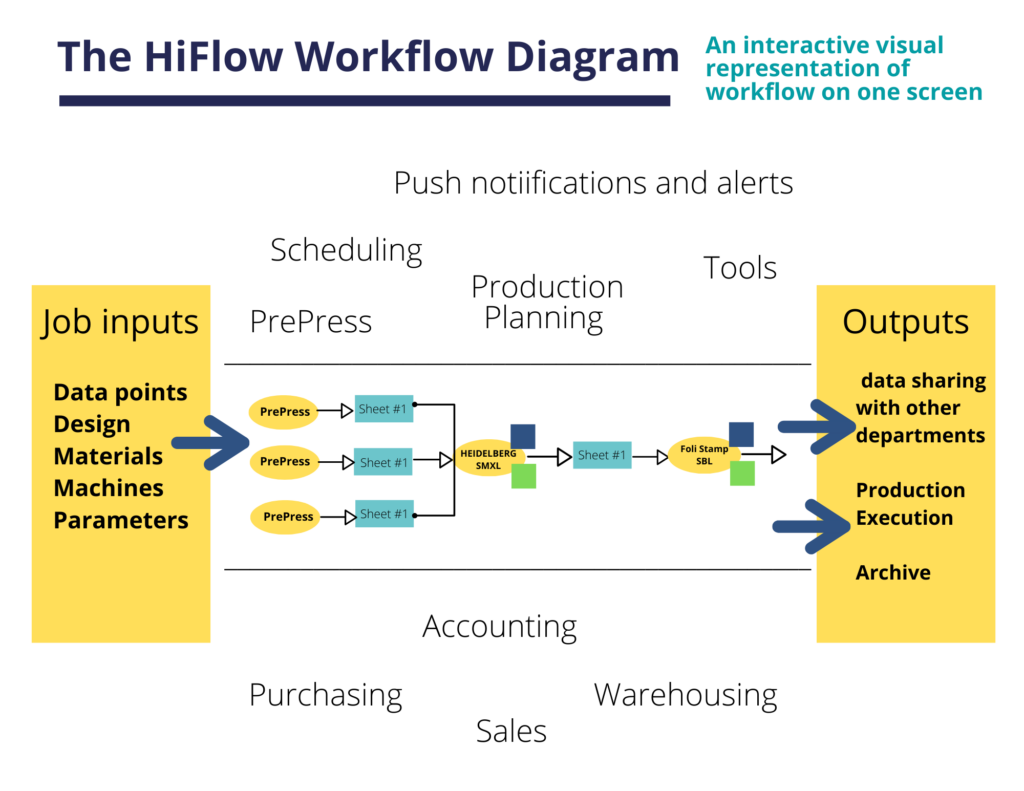

- At the core of our system is our exclusive workflow diagram that offers real workflow visibility of the production process, even the most complex packaging or POP product

- Scheduling—simplified. Workflow diagrams easily show the sequence of events in the progress of the job, so scheduling every process is a cinch.

- Harmoniously coordinate procedure paths that ensure everything is complaint to regulations adopted by the company i.e., ISO 9001, TQM

- A licensing model based on our customer’s REAL SAVINGS–the result of HiFlow Solutions system implementation before/after comparisons.

- Our CRM module makes visible to management all interactions between prospects and sales, customers and sales, and customers and customer service

- Our Customer Portal allows REAL TIME updates of, for example, Proof Out/Proof Approved to customers and company personnel

- Cost tracking in REAL TIME. Our software tracks real material consumption, shop floor data and supplier connectivity, i.e., if a supplier’s price goes up or down, estimating and purchasing will see the data in REAL TIME

- Greater profitability in areas of production by recording REAL TIME data. Management now has viewability of metrics gathered by the software and can make informed decisions, such as necessary employee training, or machine repair/maintenance/replacement

- Not just one, but a team of dedicated implementation specialists will insure a faster Go Live. Our team is printing professionals, each versed in specialty areas of packaging, label production and all types of commercial printing.

- Fast order processing. Conversion from estimate to job is quick, as calculations and workflow diagrams are brought live for customer service, planning, scheduling, shop floor in REAL TIME

OVERVIEW video

HiFlow Solutions

Is HiFlow the correct fit for your company? How does it work? What kind of features does it offer? Watch a brief overview.

Find Out More About HiFlow

HIFLOW SOLUTIONS COMPLETE SYSTEM

CUSTOM SOFTWARE SOLUTIONS

MES & MACHINE INTEGRATION